CYLINDER LINER

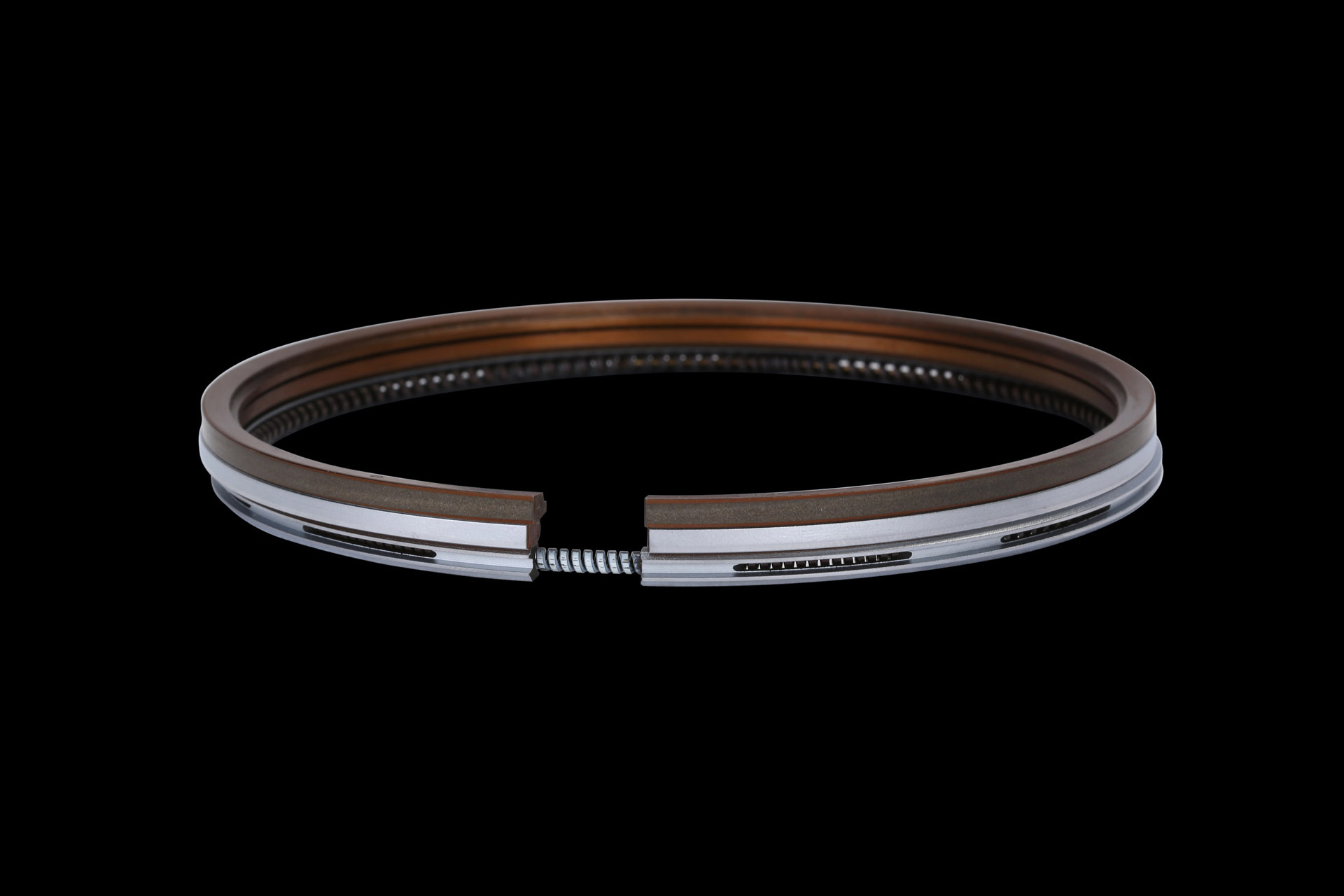

Aza Absolute’s Cylinder Liners reducing friction and extending engine life with a criss-cross pattern of grooves on the inside wall. This grooved surface maintains an adequate quantity of oil on the inside wall of the liner, which ensures sufficient lubrication at the contact point between the piston

rings and the liner. The correct angle of intersection for the groove of the walls is generally estimated at about 45°, since this promotes even lubrication and consequently extends the duration of the surfaces. However, there are cases in which different angles are created for specific materials and forms of use.

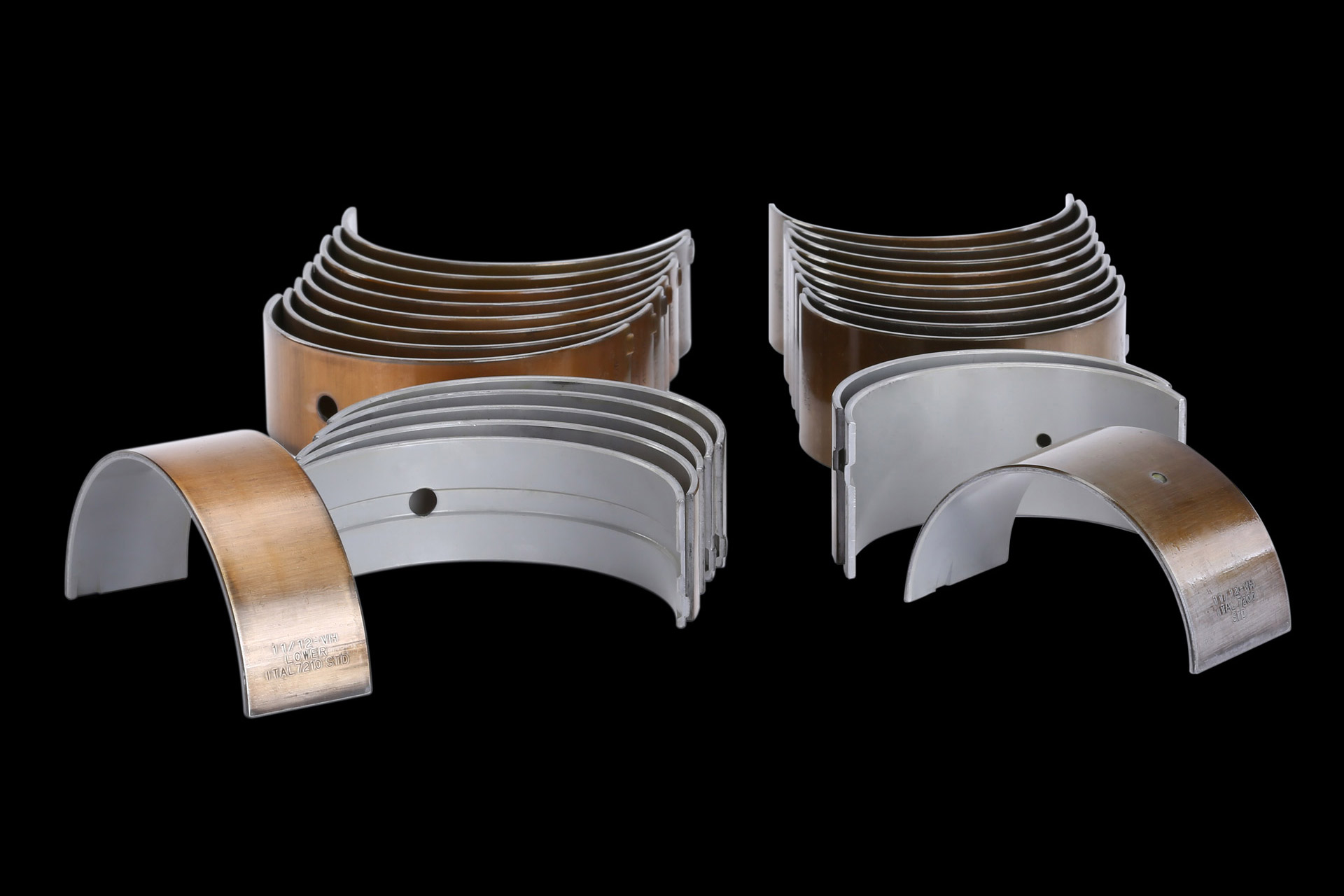

Aza Absolute’s Cylinder Liners increase resistance, and limit wear due to surfaces are rolling of the flange and the anti-corrosive surfacing of the outside wall.

Aza Absolute cylinder liners are manufactured as per ISO quality norms which require constant monitoring of the manufacturing process to satisfy strict technical specifications. All our cylinder liners are manufactured by induction melting and centrifugal casting, which are the most modern foundry processes used in manufacture of cylinder liners.

Proper hardness of Aza Absolute cylinder liner is mandatory for wear resistance For most automotive applications the appropriate hardness range is 180-220 BHN.

Hardness less than 180 BHN will cause the liner to wear prematurely, but also more than 220 BHN will cause premature wear of the piston rings, since rings are designed to function with liners of a particular hardness. Sometimes, users relate higher hardness with better quality, however, this is a common misconception. Cylinder liner should wear in a controlled manner hence it must not be too hard, or too soft.

Aza Absolute’s Cylinder Liners Advantages:

. High Resistance And Anti-Corrosion Properties,

. Low Friction,

. High Precision.